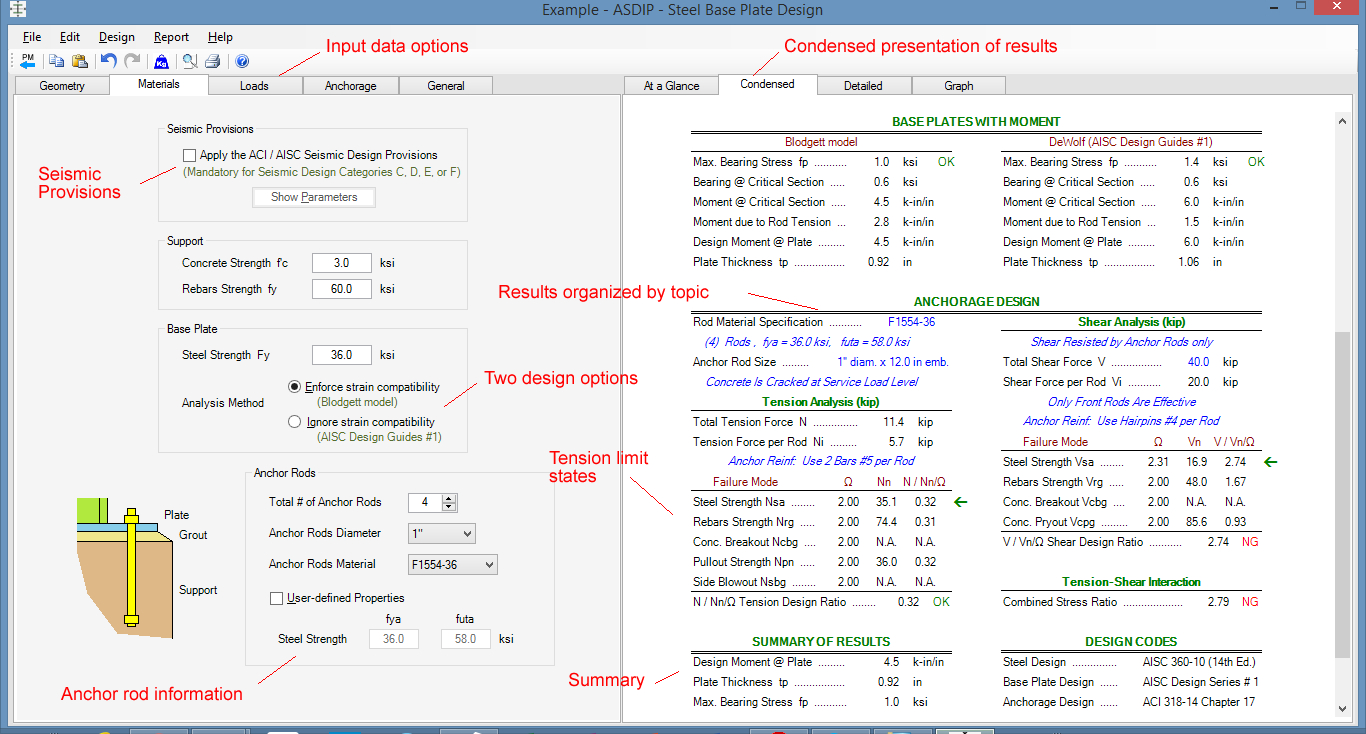

Software Notes: The software is fully available with an up-to-date version from any web browser. Software Integration: Stand-alone and integration with Sk圜iv S3D Modeler In this case, the loads can be directly transferred from the model into the connection software. Additionally, some of these connection software options can integrate with structural modeling software that engineers typically use. For each connection design, the parameters and loading information can be entered individually to quickly provide a capacity check as each piece of information is updated.

Thus, there is a second category of connection design software that focuses instead on designing a single connection at a time, also referred to as stand-alone or component-based software. Table 1 shows that Qnect and SDS/2 are two software packages that fit in this first category for connection design.Ī drawback for the first connection software type is that it can be difficult to use when trying to design a small number of connections or nonstandard connections. Additionally, the software package updates the detailer’s model with the connection design information (i.e., copes) to assist the detailer in creating steel shop drawings for the project. One of the strengths of this type of software is the minimal design time for the engineer because the software will both design and optimize all connections. These standard connections are then automatically designed throughout the entire building frame. Next, all standard connection information for the project would be entered, such as connection type, bolt size, weld size, spacing, edge distance, loading information, etc.

In this type of software, the engineer or steel detailer would model all framing members in the structure. The first category is geared toward the design of connections in bulk for an entire building structure. At this point, the question becomes, “With so many options, which software package is the best for me to use?” This article will review many of the software options currently available that specifically design HSS connections to help structural engineers make an informed decision based on their specific software needs.Ĭonnection software is split into two main categories. In situations like this, it may make sense to allow some computer software to do the heavy lifting so you can focus on the engineering task at hand. Using a spreadsheet certainly helps, but there are several conditional statements to track and verify.

Even with the STI Limit States Tables as a guide through the maze, determining the capacity of a single connection by hand can take a fair amount of time. If you have ever looked through the AISC Specification and Manual to design a structural steel connection involving HSS, then you know there are a number of limit states to check and equations to solve.

0 kommentar(er)

0 kommentar(er)